Mg Evaporation Consistency via Plasma

Ammonia (NH3) plasma + EC–HT coupling + evaporation proxy to map gradients and material-loss sensitivity during a 0–90 A sweep.

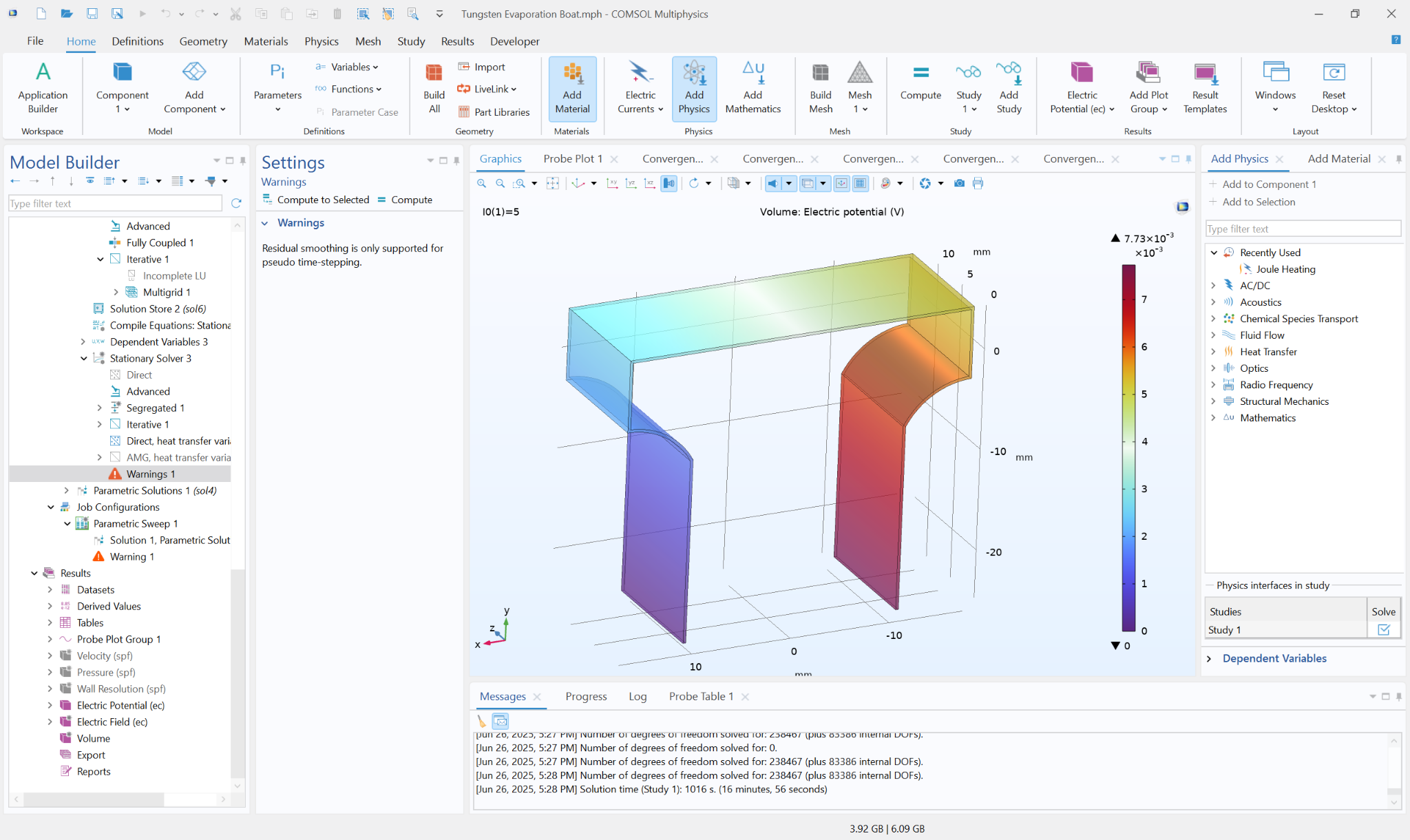

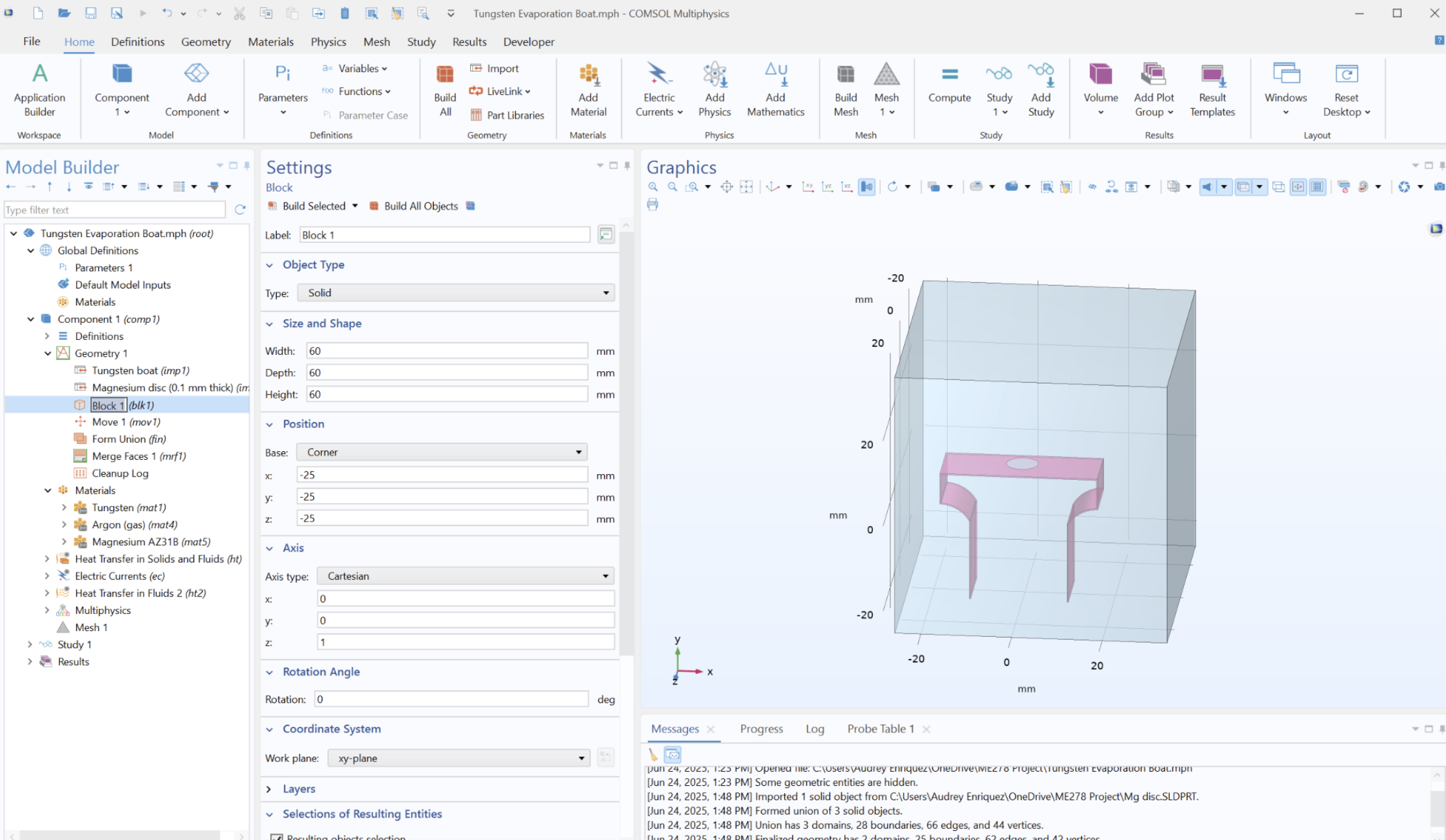

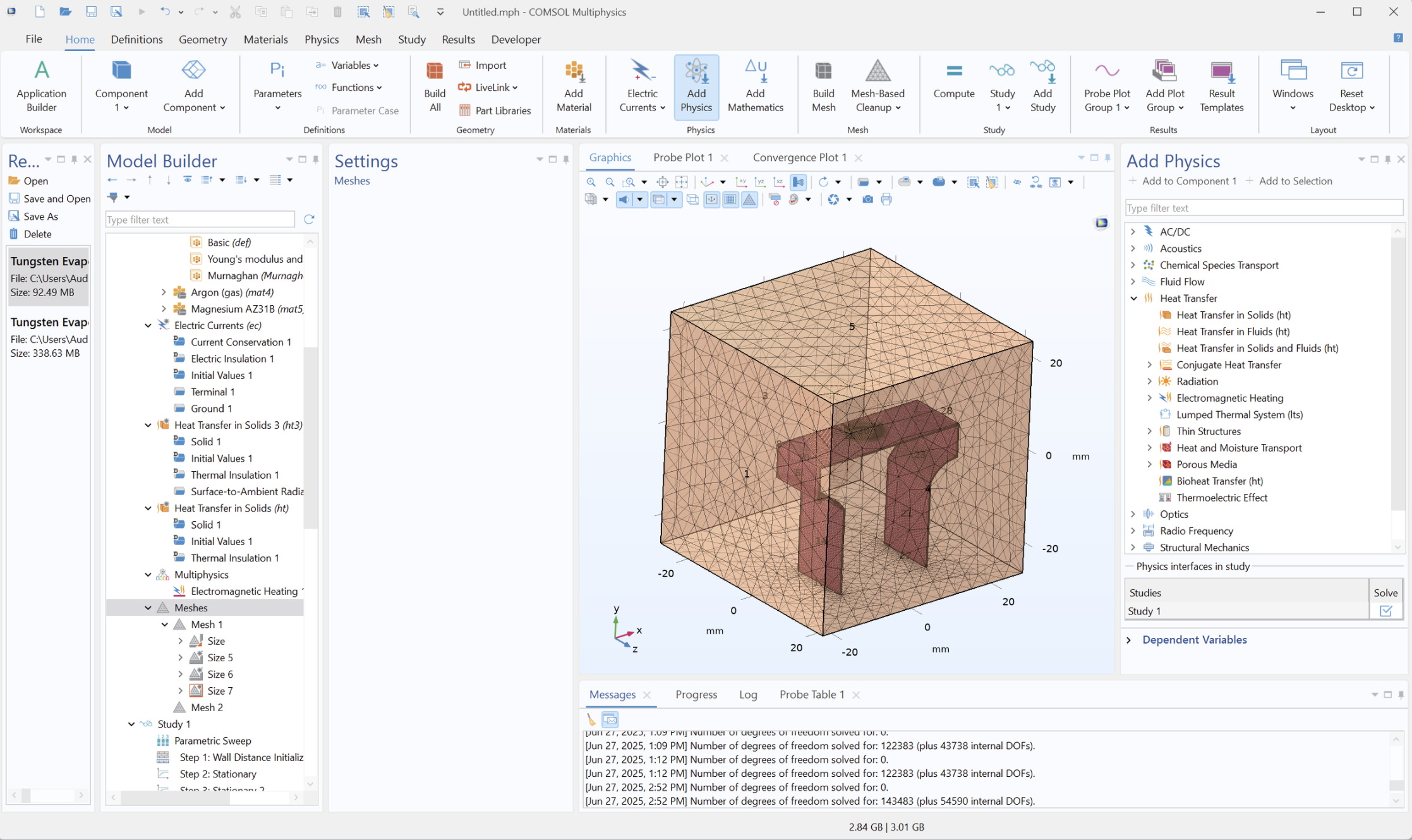

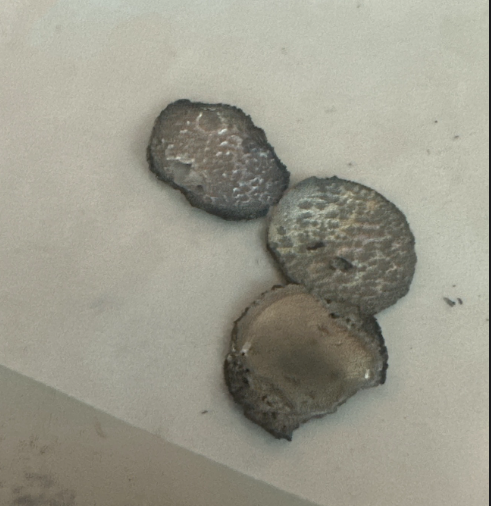

Multiphysics COMSOL model built to evaluate thickness-varied Mg disc samples under NH3 plasma exposure when direct mass-loss measurement and optical access are limited. A 0–90 A current sweep drives Joule heating to predict temperature profiles, locate peak gradients, and compare an evaporation-risk proxy across thickness cases—supporting reactive (“explosive”) Mg nanoparticle production while conserving Mg and keeping vacuum-relevant boundary behavior consistent (IP-safe enclosure + losses).

My contribution: designed and implemented the coupled EC–HT sweep model, meshing strategy, evaporation-proxy boundary, and IR overlay validation workflow. Experimental reactor/hardware belonged to my advisor’s lab; the model/workflow is mine.

What this enables (IP-safe)

- Thickness down-select: compare Mg disc thickness cases under identical NH3 plasma exposure to balance yield vs loss.

- Gradient mapping: quantify where/when thermal gradients peak across the 0–90 A sweep.

- Material-loss control: rank evaporation-risk proxy response to conserve Mg while improving run-to-run reproducibility.

- Vacuum-aware interpretation: keep boundary losses + current return paths consistent via reactor-domain enclosure.

- Hot-spot localization: identify contact/neck regions driving peak gradients to guide design/process adjustments.

- Validation pathway: IR thermography overlays to compare measured surface trends vs simulated temperature fields.

Core Simulation Features

- Gas environment: NH3 plasma represented via enclosure + boundary losses (IP-safe proxy).

- Joule heating: 0–90 A sweep sets thermal loading.

- Thickness study: Mg disc thickness is the controlled variable for yield vs loss comparisons.

- Coupled physics: Electric Currents + Heat Transfer (solid conduction + boundary losses).

- Evaporation proxy: latent-heat sink on Mg free surface (rate-linked sensitivity).

- Radiation: Stefan–Boltzmann boundary with simplified view assumptions.

Surrounding enclosure preserves current paths and boundary losses representative of the reactor environment; isolated component-only setups did not converge reliably without it.

Model assumptions & limits

- Evaporation proxy: implemented as a latent-heat sink at the Mg free surface to represent relative material-loss sensitivity when direct mass-loss measurement is constrained.

- NH3 plasma: represented through enclosure + boundary losses (not a fully coupled plasma chemistry model).

- Radiation: Stefan–Boltzmann boundary with simplified view assumptions for tractable sweep studies.

- Contacts: contact definition strongly affects peak gradients/temperatures and was treated as a key sensitivity during refinement.

Selected References

- U. Kortshagen et al., Nonthermal Plasma Synthesis of Nanocrystals, Chemical Reviews, 2016. DOI

- Wagner et al., Low-Temperature Plasma-Induced Hydrogenation of Mg Nanoparticles, J. Appl. Phys., 2023.

- COMSOL Multiphysics® docs: Heat Transfer + AC/DC modules.